The number of customers choosing PureBallast 3 for ballast water treatment on their tankers continues to grow.

Kuwait Oil Tanker Company (KOTC) is one of many ship owners choosing UV ballast water treatment over electrochlorination for large ballast water flows. Alfa Laval PureBallast 3 will be installed on vessels throughout the KOTC fleet, including VLCCs with flows of 6000 m3/h each.

TORM, an international product tanker owner and operator based in Denmark, will retrofit 36 Alfa Laval PureBallast 3 Ex systems within its existing fleet and fit PureBallast 3 Ex systems on 11 new builds. Alfa Laval will provide large-flow ballast water treatment systems for 36 vessels between 2019 and 2024.

A wide range of system advantages and dedicated technical solutions make PureBallast 3 the ideal choice for ballast water treatment on tankers.

Your tanker may require hundreds of thousands of tons of ballast water – which means large ballast water flows. PureBallast 3 handles even very large flows with a small footprint and low power consumption, thanks in part to a 1500 m3/h reactor size. Single systems can handle up to 3000 m3/h, while dual systems can be used for coverage up to 6000 m3/h.

If your tanker carries volatile cargo, it has to meet the stringent requirements for potentially explosive environments. PureBallast 3 Ex systems are configured according to ATEX and IECEx, Zone 1, IIC and T4, with redundant safety features and lamp cabinets that are located in the safe zone up to 150 m from the reactors they serve.

Installing a ballast water treatment system on deck shouldn’t mean problems for your existing submersible ballast pumps. The technical teams for Alfa Laval ballast water treatment systems and Framo pumping systems have developed a solution for providing additional pumping head when PureBallast 3 Ex is installed in a deckhouse.

The following links and downloads may be useful as you consider a PureBallast 3 solution for your tanker.

Learn more about PureBallast 3 Ex, the PureBallast 3 solution most commonly installed on tankers.

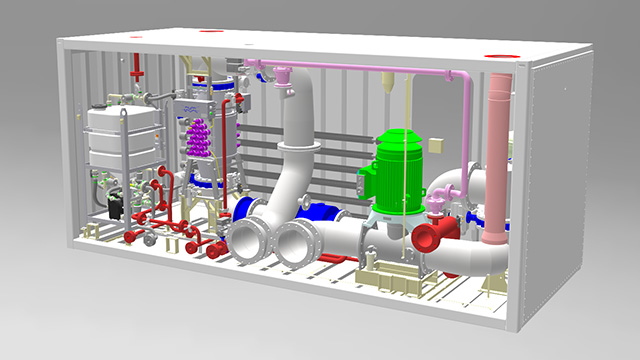

If your PureBallast 3 Ex system is installed in a deckhouse, your existing ballast water pumps may not provide enough pressure for effective backflushing. In such cases, Alfa Laval can integrate a booster pump unit (BPU) into the deckhouse. This protects your tanker’s cargo offloading rates without changes to its existing pumps.

Find out why UV ballast water treatment today is often a smarter solution for large flows than electrochlorination.

Watch The Maritime Standard’s interview with Peter Sahlen, R&D Manager for PureBallast, at the 2018 TMS Tanker Conference.

Let’s talk about the specific challenges you face in ballast water treatment. With our many years of experience, we can guide you to the right PureBallast 3 solution for your tanker.