LeviMag

De Alfa Laval LeviMag® is een aseptische magnetische mixer die een gepatenteerde zwevende waaier en een geavanceerd ontwerp gebruikt om tot de laatste druppel te mengen en de productopbrengst te maximaliseren. De compacte, energiezuinige en onderhoudsvriendelijke magneetmenger is perfect voor zuivel, levensmiddelen, dranken en andere toepassingen met hoge eisen voor hygiënische productie.

Maximale procesbesparing, minimaal productverlies

- Geoptimaliseerde doorstroming met hogere efficiëntie en minder energieverbruik

- Mengen tot de laatste druppel voor maximale opbrengst dankzij lage agitatie en droogloopvermogen

- Geoptimaliseerde Cleaning-in-Place dankzij volledige aftapbaarheid

- Minimale downtime dankzij eenvoudig onderhoud

Maximaliseer de productopbrengst en realiseer snel rendement op uw investering dankzij het droogloopvermogen van de Alfa Laval LeviMag magnetische mixer. Zorgen voor een zachte productbehandeling is gemakkelijk dankzij efficiënt mengen bij zeer lage snelheden. Bovendien dragen het open ontwerp en de lage rotatiesnelheid tijdens het reinigen bij aan een effectieve verwijdering van resten en minimaliseren ze het risico op besmetting door slijtagedeeltjes.

LeviMag® magnetische mixertechnologie

Meng tot de laatste druppel dankzij de zwevende waaier met vier vleugels van de Alfa Laval LeviMag magnetische mixer. Het minimaliseren van slijtage en zorgen voor aftapbaarheid is eenvoudig omdat er geen direct contact is tussen de draagvlakken en er geen dode zones zijn.

Service

Zorg voor meer inzetbaarheid dankzij slijtvaste lagers die gemakkelijk te onderhouden zijn en gemakkelijk door operators ter plaatse kunnen worden-vervangen. Geen lijm of krimppassing nodig. Dit minimaliseert de uitvaltijd. Bovendien zijn er geen reservewaaiers nodig. Hulpmiddelen voor eenvoudig onderhoud zijn ook beschikbaar.

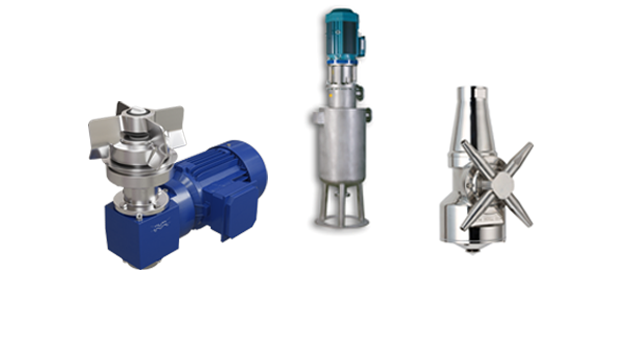

Productmodellen

De Alfa Laval LeviMag magnetische mixer is verkrijgbaar in vier formaten met mengsnelheden van 10 tot 600 tpm, als het zwevende waaierontwerp van de mixer wrijving elimineert. Dit biedt een grotere procesflexibiliteit om een breed scala aan vloeistoftypes en mengtaken aan te kunnen, zoals hoge-intensiteit en zachte productmenging.

Hoe het werkt

Een radiale turbine die in de tank is geïnstalleerd, wordt geroteerd via het koppel van een magnetische koppeling. Hierdoor ontstaat een vermenging van de vloeistof in de tank. Het gepatenteerde, zwevende ontwerp van de waaier zorgt ervoor dat de menger volledig leeg kan lopen en droog kan lopen, waardoor hij tot de laatste druppel kan mengen, waardoor een maximale opbrengst wordt gegarandeerd.

Het unieke ontwerp van de magnetische koppeling van Alfa Laval zorgt altijd voor de levitatie van de waaier. Dit maakt de volledige aftapbaarheid van procesvloeistoffen en de vrije stroming van CIP-vloeistof en stoom rond alle onderdelen van de mixer mogelijk, waardoor een grondige reiniging wordt gegarandeerd. De levitatie van de waaier elimineert ook axiale slijtage.

360° service- en onderhoudsvideo's

Hoe kunt u het vrouwelijke lager vervangen en monteren

Hoe kunt u het mannelijke lager demonteren en vervangen

Deel van een breed assortiment mengers

Alfa Laval biedt een uitgebreid assortiment mengapparaten bedoeld voor hygiënische toepassingen in de zuivel-, voedsel-, dranken-, thuiszorg-, persoonlijke verzorgings-, biotechnologie- en farmaceutica-industrieën.

- Alfa Laval Hybrid Powder Mixer

- Alfa Laval LeviMag® UltraPure Magnetic Mixer

- Alfa Laval LeviMag® Magnetic Mixer

- Alfa Laval Rotary Jet Mixer

Voor een breder mengbereik, verken de verschillende productcategorieën: roerwerken en mixers.

Wellicht hebt u ook interesse in…

ALB

Ons bodemroerwerk ALB biedt mengoplossingen om te voldoen aan alle vereisten in voedingsmiddelen, zuivel, drank, farmaceutica, biotechnologie en cosmetica.

Sani

Toftejorg-tankwasmachines met roterende sproeibol, die speciaal zijn ontworpen voor hygiënische toepassingen, bieden een uitstekende reinigbaarheid en aftapbaarheid, en een eenvoudig, kosteneffectief onderhoud.

Hybrid Powder Mixer

Met deze kosteneffectieve, tweetraps, inline poederoplossingseenheid kunt u snel natte en droge ingrediënten tot een homogeen mengsel mengen en oppompen en deze is daardoor ideaal voor de zuivel-, voedingsmiddelen- en drankenindustrie.

Tien supertips: tankuitrusting

Hier vindt u enkele tips en servicevideo's om u te laten zien hoe u uw tankuitrusting in topconditie houdt.

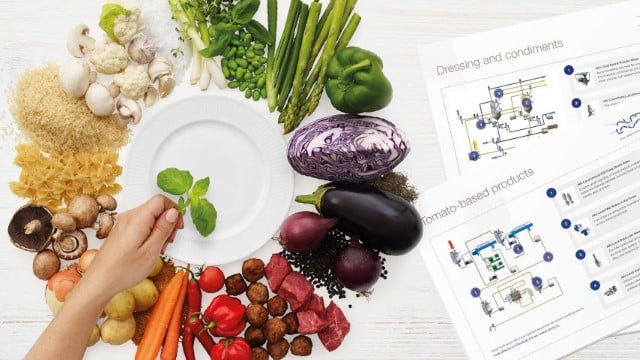

Food Logic

De hygiënische apparatuur van Alfa Laval combineert uitstekende prestaties met productvriendelijke behandeling om kwetsbare ingrediënten te beschermen en bij te blijven met de trends in de voedingsindustrie. De apparatuur biedt het hoofd aan vier belangrijke uitdagingen: het leveren van voedselproducten aan consumenten tegen een concurrerende prijs, het optimaal benutten van grondstoffen, het verminderen van afval en emissies en het leveren van veilige en hygiënische voedselproducten.

CAD-portal

Download de productmodellen in neutrale of native CAD-bestandsindelingen. Het is ook mogelijk om 3D PDF-bestanden te downloaden.

Animaties

Ga naar de animatiesite en kijk in een product om meer inzicht te krijgen in hoe het werkt.