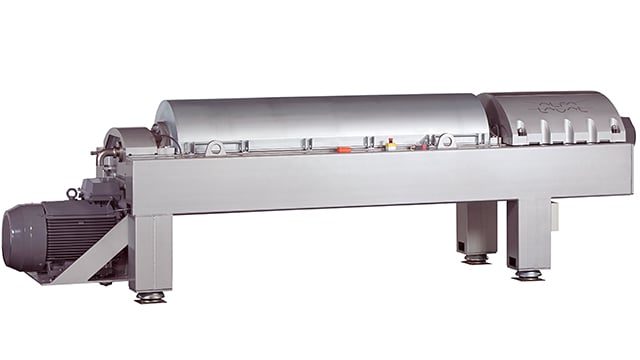

Foodec Hygiene Plus: geavanceerde voedselverwerking

De vereisten van de voedingsindustrie op het gebied van hygiëne zijn volop in ontwikkeling. Daarom verbeteren we bij Alfa Laval onze decanteeroplossingen continu. We voorzien ze van hygiënische kenmerken en ontwerpen die nieuwe standaarden zetten. De Alfa Laval Foodec Hygiene Plus moet een optimale uptime leveren dankzij zijn uitstekende betrouwbaarheid door gebruik te maken van technologieën voor geavanceerde voedselverwerking. De Foodec Hygiene Plus is een decanter voor voedingsmiddelen die speciaal is ontworpen om beter te voldoen aan de behoeften van de evoluerende voedingsindustrie.

Centrifugatie in de voedingsindustrie: extra kenmerken speciaal ontworpen om de niveaus van hygiëne een boost te geven

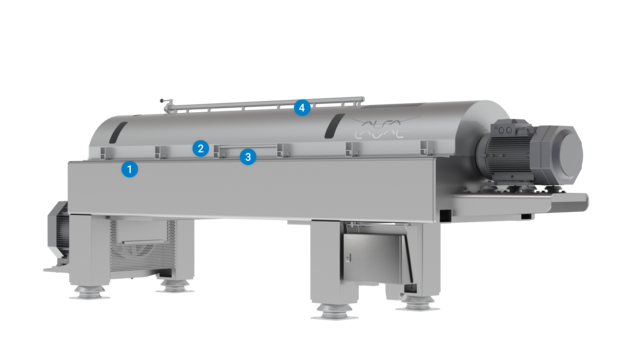

- De afvoeropening zorgt ervoor dat er na bedrijf zo min mogelijk residu achterblijft in de decanteercentrifuge voor voedingsmiddelen, waardoor reinigen efficiënter verloopt.

- De met het product bevochtigde oppervlakken in de Foodec Hygiene Plus zijn speciaal ontworpen en ontwikkeld om zo glad mogelijk te zijn voor extra gemakkelijke en effectieve reiniging. Het gladde oppervlak voorkomt ook biofilmvorming.

- De CIP-toevoerbuis (Cleaning-In-Place) en de bedrijfskritische doodlopende gebieden van de toevoerbuis zijn nu gemakkelijker te reinigen. Denk daarbij vooral aan het gebied rond de toevoerzone van de decanter en de tapse conussectie, die nu ook veel effectiever kunnen worden gereinigd.

- Het nieuwe, geoptimaliseerde ontwerp van de geïntegreerde CIP-balk maakt het gemakkelijker om elk onderdeel van de binnenkant van het frame en de buitenkant van de kom te reinigen. Tegelijkertijd beperkt het de vereiste hoeveelheid reinigingsmiddel tot een minimum.

Alfa Laval Foodec decanteercentrifuges zijn de beste in hun klasse als het gaat om prestaties en efficiëntie. De Foodec Hygiene Plus is standaard voorzien van extra kenmerken die speciaal zijn ontworpen om de niveaus van hygiëne een boost te geven. Deze kenmerken zijn ook te installeren op bestaande decanters. Zo krijgen oudere oplossingen een upgrade om te voldoen aan bestaande eisen en verwachtingen op het gebied van hygiëne. Daar waar hygiëne extra belangrijk is, kunnen wij ook extra functies aanbieden om de reinheid nog verder te boosten.

TrueStainless™

Speciaal ontworpen voor langdurige en ongeëvenaarde hygiëne.

TrueStainless™ betekent dat wij massief roestvast staal gebruiken voor het frame en andere belangrijke onderdelen die in contact kunnen komen met corrosieve atmosferen. Dat leidt tot een optimale hygiëne en een langere levensduur van de apparatuur.

SaniRibs®

De schonere, efficiëntere manier om vaste stoffen te transporteren.

Onze unieke dichtgelaste ribben zorgen voor een optimale wrijving, waardoor vaste stoffen beter en efficiënter worden getransporteerd. Deze innovatieve technologie elimineert ook hotspots voor ziekteverwekkers. Het reinigingsgemak betekent langere productieruns, minder handmatig onderhoud en betere winstmarges.

Documenten

Productbrochure

Waarom wordt voedselveiligheid steeds belangrijker voor de voedingsindustrie?

Voedselveiligheid en hygiëne in de voedselverwerking winnen aan belang, waardoor de voedingsmiddelenindustrie hogere eisen stelt aan de voedselverwerkende apparatuur en centrifugatie.

- Wat is voldoende hygiëne? Het antwoord op die vraag is in de loop der jaren drastisch veranderd door de toegenomen bewustwording van voedselveiligheid. Ook hebben meer geavanceerde data en onderzoek ons in staat gesteld om verontreinigingen en gevaren waar te nemen die eerder misschien niet waarneembaar waren.

- Het handhaven van hygiëne in apparatuur voor voedselverwerking speelt een essentiële rol als het gaat om het garanderen van een perfect eindproduct met exact de juiste smaak en textuur.

- Het handhaven van het juiste niveau van hygiëne kan ook de productiviteit van a tot z verbeteren, terwijl efficiëntere reinigingsprocessen helpen om ongeplande downtime te minimaliseren.

De evoluerende vraag is wat ons voortdurend drijft om oplossingen te ontwikkelen met behulp van technologieën voor geavanceerde voedselverwerking. Oplossingen die de verwachtingen van onze klanten op het gebied van hygiëne en prestaties in een decanteercentrifuge overtreffen. Daarom hebben wij een state-of-the-art oplossing ontwikkeld voor de voedingsindustrie: de Alfa Laval Foodec Hygiene Plus.

Service

Effectief onderhoud van Foodec Hygiene Plus decanters voor voedingsmiddelen is essentieel om naast de best mogelijke niveaus van hygiëne ook optimale procesprestaties te garanderen.

Afhankelijk van de procesomstandigheden, zoals bedrijfstijd, soort grondstof, procestemperatuur en het aantal CIP-cycli, raadt Alfa Laval aan de decanter minstens om de 4-6 maanden te laten inspecteren en minstens eenmaal per jaar een grote servicebeurt te laten ondergaan. Gekwalificeerde buitendienstmonteurs van Alfa Laval kunnen service en inspectie ter plaatse uitvoeren of in een Alfa Laval servicecenter. Zo kunt u beslissen welke optie het best werkt voor uw specifieke behoeften.

Een cruciaal onderdeel van het onderhoud van uw decanter is het in topconditie houden van uw kom en transporteur. Het speelt een sleutelrol om consistente prestaties en optimale hygiëne veilig te stellen. Reparatie van de kom en/of transporteur moet worden uitgevoerd in een Alfa Laval servicecenter.

Dankzij connected services, zoals monitoring op afstand en online ondersteuning, kunnen onderhoudsintervallen worden verlengd. Onderhoud, reparaties, conditiemonitoring en toegang op afstand kunnen als een pakket worden aangeboden in één serviceovereenkomst. Op maat van uw specifieke behoeften. Alfa Laval biedt ook training voor onderhoudspersoneel ter plaatse.

Neem contact met ons op en krijg een offerte voor een serviceovereenkomst die voldoet aan uw specifieke vereisten.