WSAC service and parts

Prepared for emergency breakdown situations? Don’t wait until your tube bundle fails. Schedule replacement of critical components in advance and avoid downtime delays by stocking parts with longer lead-times. In addition to annual inspection, WSAC systems should be serviced on a regular basis.Avoid downtime in critical processes – schedule an integrity audit by a qualified Alfa Laval field service technician today.

Downloads

Service posters

Genuine parts for guaranteed performance

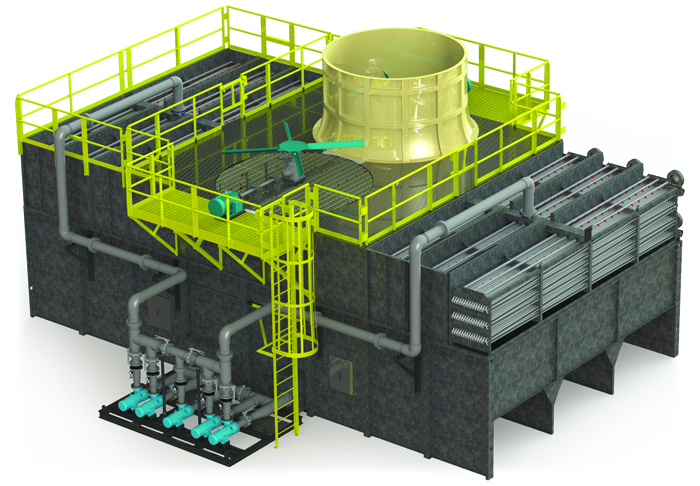

Fan system

Motor, prop fans, centrifugal fan wheels, wheel housings, bearings, fan shafts, gear reducers, belts, fan shrouds, vibration switches and drift eliminators.

Ancillary components

Water make-up valves, pump screens, temperature switches, pan heaters, casing panels, caulk and sealing tape.

Spray system

Spray pumps, pump shafts and impellers, spray distribution piping, spray nozzles and pressure gauges.

Tube bundles

Replacement tube bundles, tube bundle covers and gaskets. Completely cleanable and serpentine tube bundles designed to meet ASME/ TEMA/API specifications and original dimensions to minimize installed cost.

System maintenance

Fan maintenance

- Lubricate fan motors monthly.

- Check oil level on gear drives monthly, add oil if necessary.

- Check fan blades for tightness annually, adjust pitch if necessary.

- Check shaft/coupling condition annually, if applicable.

- Check air louvers for proper operation monthly, if applicable.

- Check that drift eliminators are clean and secure monthly, if applicable.

Water treatment and blowdown maintenance

- Check bleed rate weekly and adjust if necessary.

- Check for biological growth in the basin and coil tubes weekly. Consult a water treatment specialist if growth is not under control.

System integrity check

- Check integrity of major components and casing panels annually, replace if necessary.

Spray maintenance

- Check spray distribution system weekly. Check spray nozzles coverage and clean as necessary.

- Check operating water level in basin weekly, adjust float valve if required.

- Clean and flush basin annually.

- Check for casing leaks monthly, repair as necessary

Tube bundle maintenance

- Check tube bundle pressure drop monthly, clean internally if necessary

Pump maintenance

- Lubricate pump motors monthly.

- Check pump seal weekly, replace if necessary.

- Check pump screen weekly. If environment is extremely dirty, clean screens daily.