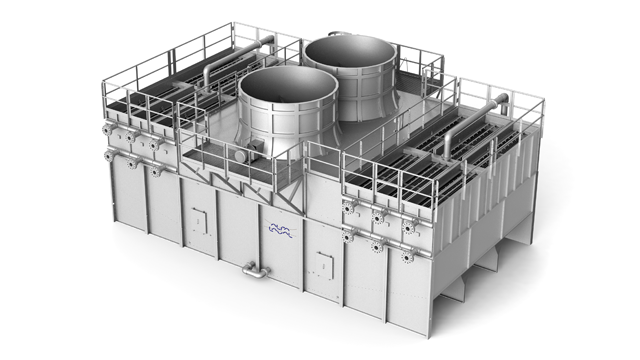

Services for Niagara Wet Surface Air Coolers

We help you ensure sustainable operation of your Alfa Laval Niagara Wet Surface Air Coolers (WSAC), both from a business and an environmental perspective. With Alfa Laval as your service and maintenance partner you have the full backing of our process and equipment specialists. They help you reduce water and energy consumption, increase performance, secure uptime and optimize lifecycle costs. We are ready to assist you throughout the entire lifespan of your system.

Alfa Laval Niagara WSAC product leaflet.pdf

2018-06-18 1050 kBService offerings for Niagara WSAC field-erected systems.pdf

2018-06-18 329 kBService offerings for Niagara WSAC modular systems.pdf

2018-06-18 287 kBService offerings for Niagara WSAC packaged systems.pdf

2018-06-18 272 kBTen top tips to keep your field-erected Alfa Laval Niagara WSAC system in tip top condition.pdf

2018-06-18 174 kBTen top tips to keep your modular Alfa Laval Niagara WSAC system in tip top condition.pdf

2018-06-18 134 kBTen top tips to keep your packaged Alfa Laval Niagara WSAC system in tip top condition.pdf

2018-06-18 131 kBEvaporative cooling service offerings

Troubleshooting

Our evaporative cooling service technicians are never more than a phone call away when you need help. They are available 24/7 and in case your problem cannot be solved remotely, they can be on your site within a couple of days.

- Fast access to expert help

- Quick access to on-site assistance

- Minimum downtime

- Maximum safety

Spray nozzle replacement

An evaporative air conditioning service expert can provide recommendations if your existing spray nozzles become clogged. We now offer an anti-clog nozzle which allows for debris up to 1" diameter to pass through. The nozzle is a direct replacement to older styles.

- Clog resistant design

- Quarter turn, quick disconnect for easy install

- No modifications required to existing spray system

- Keeps your equipment running at peak performance

Spare parts

We strongly recommend that you only use original air cooler parts for your WSAC system. All components have been carefully selected for durability and safe operation. Using spares from other suppliers may compromise reliability.

- Complete range of spare parts

- Maximum reliability

- OEM quality

- Recommendations on which long-lead-time parts to keep in stock

Training

Make sure new and existing personnel know how to operate and maintain your WSAC system. We support you with customized training in safe operating practices, system checks and maintenance procedures.

- Safe operations

- Low maintenance costs

- Fast response when issues arise

- Faster maintenance stops

Installation and commissioning supervision

We recommend letting one of our service engineers supervise the installation and commissioning of our WSAC systems to ensure the equipment is correctly installed and tuned for high cooling efficiency. You get:

- Fast and trouble-free installation

- High cooling performance

- Maximum reliability

- Low water and energy consumption

Condition audits

Get full insight into the condition of your WSAC cooling system with a condition audit. During one of your scheduled maintenance stops, an equipment specialist makes a complete inspection of your system and advises you on:

- Performance optimization

- Maintenance actions and priorities

- Possible upgrades

- Training

Equipment upgrades

When operating conditions change, an upgrade is often a cost-efficient way to meet the new requirements, such as higher capacity. We help you through the entire process from analysis to installation:

- Increase capacity

- Prolong equipment lifetime

- Reduce evaporative cooling service requirements

- Maximize uptime

Performance audits

Have one of our WSAC experts make an in-depth evaluation of the performance of your equipment. You will get valuable advice on possible upgrades and how to optimize the operation of your WSAC unit to:

- Increase cooling capacity

- Optimize operating costs

- Minimize water and energy consumption

- Maximize reliability