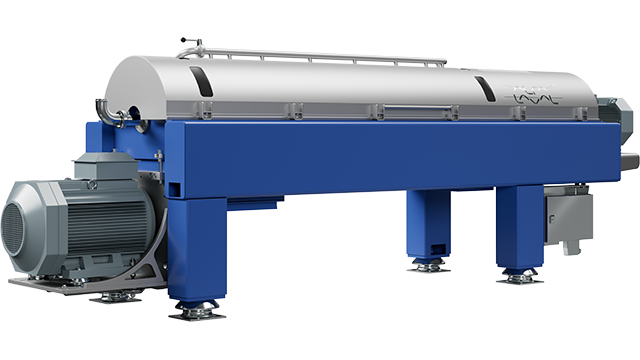

Prodec

Alfa Laval industrial centrifuges are engineered to improve your separation processes. Prodec offers a reliable, cost-effective solution for demanding processing operations, setting the benchmark in 2 and 3 phase separation. A water oil separator suitable for a broad range of industries, including mineral processing, battery recycling, ethanol, biofuels, chemical production and starch dewatering.

Experience superior solid-liquid separation efficiency with Alfa Laval Prodec decanter centrifuges

- Maximize product recovery in demanding industrial applications through continuous, uninterrupted operation

- High-performance processing, packed into a compact design with a small footprint

- Advanced conveyor technology enables precise control over the separation process, improving consistency across varying feed conditions

- Durable engineering with optimized materials for reliable performance even in erosive, corrosive and high-temperature environments

- Smart cleaning powered by Alfa Laval’s integrated control technology reduces downtime and extends the life of your separation equipment

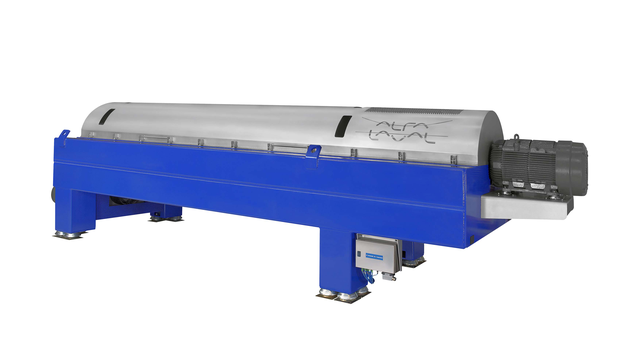

Improving the energy efficiency of Alfa Laval separation equipment

The bowl can be equipped with special power plates or tubes that harness the hydraulic energy to reduce the overall power consumption. Some of the discharge velocity from the liquid leaving the unit is captured and re-directed to contribute to bowl rotation. This reduces the velocity of the discharged liquid, which in turn reduces overall power requirements. The unique Alfa Laval direct drive system automatically controls the conveying speed to ensure optimum solids dryness, irrespective of acceptable variations in the feed flow.

From dewatering heat-coagulated potato protein, maize gluten and wheat starch to protein splitting in starch production, Prodec centrifuge decanters excel in food and starch processing. Their robust design also ensures optimal performance when handling erosive, corrosive and high-temperature slurries in mineral processing, pulp and paper, coal tar and steel industries. In addition, they play a critical role in ethanol and biofuel production, supporting sustainable energy solutions.

Which decanter features make a difference in your industrial separation process?

Available as 2 or 3 phase separation designs, this Alfa Laval water oil separator can be tailored to specific requirements using corrosion resistant materials, enhanced wear protection and effective cleaning options. The bowl and conveying speed, pond depth in the bowl and feed rate are adjustable to improve the performance and operate reliably and efficient.

The Prodec decanter centrifuge comes with an Alfa Laval decanter automation control package as standard, pre-installed and factory-tested to make sure you get the most out of your set-up. It also helps minimize costs for installation, commissioning, operation and maintenance.

3Phase

Separating suspended solids from two liquid phases in one step

Accurate adjustment possibilities and long retention time ensure separation in three distinct fractions in one run. 3Phase separation ensures an accurate and stable interphase level, which is key for coping with variations in feed compositions and flow rates. The unique design creates low agitation, resulting in high clarity in both liquid phases.

DeepPond

High separation performance and energy efficiency

Increasing the pond depth inside the bowl creates a larger volume, leading to longer retention time and improved separation performance. The DeepPond design delivers high solids dryness and clean centrate from your decanter centrifuge, even at high flow rates.

VecFlow™

Rotating feed zone

Low turbulence in the decanter centrifuge bowl is essential for high separation performance and low power consumption. The VecFlow™ rotating feed zone gives you maximum performance with minimal turbulence.

OilPlus

Maximized oil extraction

Special solids and fluid interaction to gain maximized oil recovery.

FlightGuard

Robust wear protection for conveyor flights

FlightGuard wear protection consists of tiles welded to the conveyor, providing robust wear resistance and prolonged uptime in highly abrasive applications.

How do Alfa Laval centrifuge decanters work?

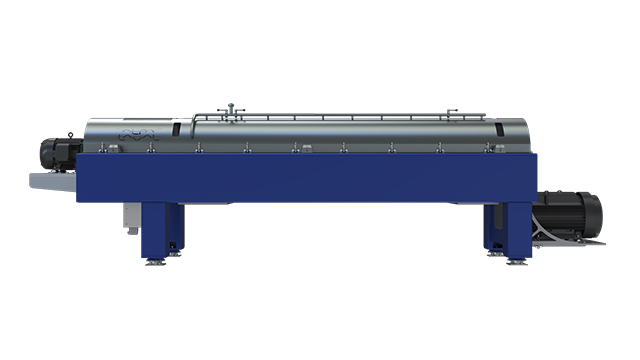

The decanter centrifuge working principle is based on separation inside a horizontal cylindrical bowl equipped with a screw conveyor. The product is fed into the bowl through a stationary inlet tube and is smoothly accelerated by an inlet rotor. Centrifugal force immediately makes the solids build up on the wall of the bowl, ensuring effective solid-liquid separation.

The conveyor rotates in the same direction as the bowl but at a different speed, moving solids toward the conical end where they exit through the solids discharge openings into the casing. Separation in a water oil separator takes place along the entire length of the cylindrical part of the bowl, and the clarified liquid exits through adjustable outlet tubes.

Industrial separation success stories

The Alfa Laval Prodec series of industrial decanters provides equipment for all types of production lines, regardless of raw material. Explore stories where our application experts have supported customers with valuable advice and efficient solutions throughout the design and engineering process.

Prodec decanter service

Do you need service for your 2-phase or 3-phase decanter? With our Global Service Network, help is always close at hand. No matter where or when you need us, we keep your Alfa Laval industrial centrifuge running at peak performance—giving you more uptime and complete confidence for the life of your equipment.

Explore other industrial decanter centrifuges for enhanced oil separation

Let us help you

Our industry experts are readily available to collaborate with you in identifying opportunities and evaluating challenges, providing unique solutions that accelerate results and optimize your return on investment.