Pharma-line Point of Use

A compact module developed for point of use cooling in pharmaceutical water systems. The Pharma-line Point of Use module for the pharmaceutical industry is designed as a subloop in hot water systems keeping it sanitized when not in use.

Efficient point of use cooling

- Easy installation: The Pharma-line Point of Use is built as a plug-and-play module for easy installation

- Hygienic design: Designed to eliminate risk of contamination. No internal welds, and fully drainable on the product side with no dead legs

- Full supply chain transparency with Alfa Laval Q-doc documentation

- Fast response: When switching from 'stand-by mode' to 'cooling mode', cold water is available within seconds

- Minimized waste of purified water due to the low hold-up volume and fast response

The Pharma-line Point of Use cooler meets the stringent hygienic standard imposed by both control authorities and industry. With a unique design that gives high shear force and turbulence, it minimizes risk of bio-film build-up and ensures an efficient heat transfer. All product wetted parts in the Pharma-line Point of Use cooler are electropolished and the tubes as seamless. For quick and easy installation, the Pharma-line Point of Use cooler is supplied as a complete insulated module with a pitot tube arrangement and either manual or automatic valves. Installed in a pharmaceutical water system, the Pharma-line Point of Use module can be regarded as a sub-loop of the main loop.

How it works

Operating principles

The Pharma-line Point of Use heat exchanger in pharmaceutical industry is made up of three tubes positioned concentrically within each other. The product flows in the middle channel meeting the service media in the inner and outer channel to get full countercurrent flow and thereby efficient heat transfer.

Installed as a complete point-of-use cooler the heat exchanger is kept sanitized all the time. In stand-by mode, part of the hot WFI is taken via the pitot tube for a continuous flow through the heat exchanger. Hot WFI(Water for injection) is possible to take out through the user point. When cold WFI(Water for injection) is needed, the cooling mode is turned on, which closes the recirculation valve and opens the cooling water valve. Cold WFI is available within seconds and there is no need for flushing or draining of the system before drawing WFI or PW.

Standard sizes

The Pharma-line Point of Use is available in three standard sizes with a heat transfer area ranging from 0.3 m² to 0.7 m², allowing a flow rate up to 1200 l/h.

Close at Hand Catalogue

Alfa Laval's hygienic equipment product catalogue "Close at hand" includes product leaflets, performance curves, links to animations, brochures and lists for ordering purposes.

You might also be interested in...

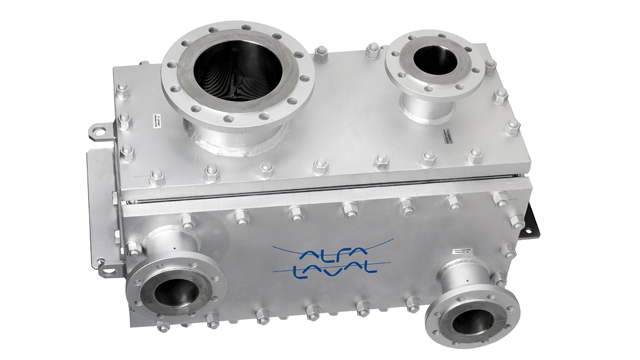

Compabloc Free Flow

A compact condenser with very high heat transfer efficiency specifically designed for the pharmaceutical industry and the high hygienic requirements of modern API production. Learn more on this page.

Pharma-line

A high-quality shell-and-tube heat exchanger especially developed to meet the high hygienic demands of the pharmaceutical industry.

Tank cleaning equipment

Using the right tank cleaning device can significantly reduce downtime, while using fewer resources such as water, cleaning agents and energy. Our devices are also designed to increase plant safety by eliminating confined space entry for manual tank cleaning.

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.

Heat exchangers

Ten top tips: Hygienic GPHE

near Newsletter

To keep you updated on important sustainability issues and opportunities in your industry and processes.