Evaporators

Elevate product quality, boost energy savings, and reduce costs with Alfa Laval evaporation systems. Engineered for maximum thermal efficiency and long-term reliability, our advanced evaporators help you achieve higher concentration levels. Versatile and purpose-built, they adapt to your process needs, improving uptime while supporting your sustainability goals.

Evaporators that help reduce costs and environmental footprint

- Achieve higher product concentrations while increasing throughput

- Cut energy use and emissions with efficient multi-effect configurations

- Enhance sustainability efforts with thermal or mechanical vapour recompression (MVR) and waste heat recovery

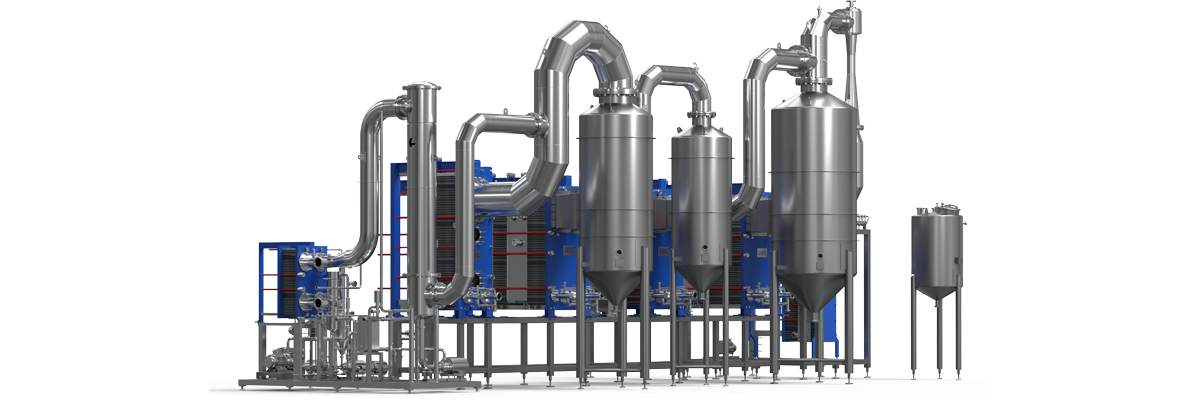

- Save on installation with compact, space-efficient designs

- Move toward zero liquid discharge when combined with other Alfa Laval technologies

Reduce your total cost of ownership while advancing your sustainability goals. Alfa Laval evaporation systems combine high thermal efficiency with compact, easy-to-integrate designs – ideal for food manufacturing environments.

Compared to conventional systems, they deliver better energy savings, reduced fouling, and consistently high product quality. Engineered for simple installation and maintenance, they help you achieve higher product quality while cutting energy use and emissions. Whether you’re upgrading or expanding, Alfa Laval makes it easy to scale without compromise.

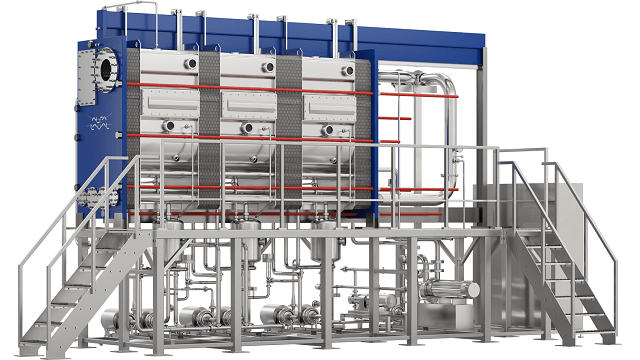

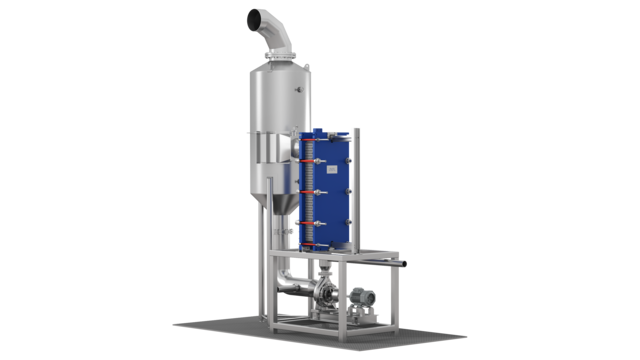

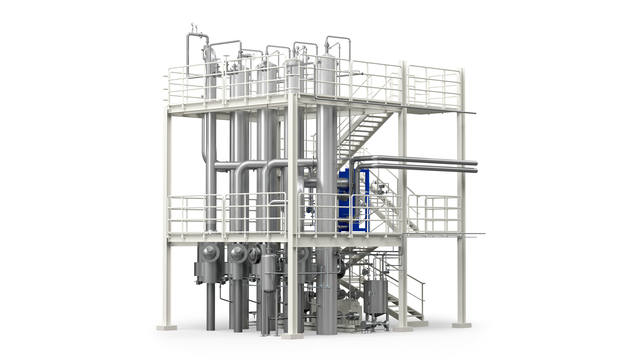

Compact, flexible and built for the future

As your production needs evolve, Alfa Laval evaporators are designed to grow with you. Their modular design reduces structural requirements, making it easy to scale capacity. Automation and clean-in-place functionality help ensure smooth operation, minimal downtime, and reliable hygiene.

Trusted by industry leaders worldwide

Want to collaborate with a world-leading supplier of advanced evaporation systems? Alfa Laval has decades of experience delivering solutions for the food, dairy, beverage, and biotech industries. We focus on helping customers increase efficiency, safety, and profitability, with support that extends well beyond installation.

Maximum uptime with expert support

Alfa Laval is with you every step of the way, with tailored service agreements. Fast access to readily available spare parts, remote monitoring, and connected services enable proactive maintenance. Plus, you can tailor a service agreement to meet your exact needs – from commissioning and troubleshooting to long-term optimization and complete retrofits. We help you get the most from your evaporation investment.

Optimizing uptime

Alfa Laval offers dedicated service to optimize your evaporation system and ensure more uptime:

- Connected services provide remote support and assistance to achieve improved uptime, high yield and optimized maintenance frequency

- Spare parts for all key equipment readily available

- Service agreements for tailor-made support – from spare parts to troubleshooting and retrofits

Happy customers

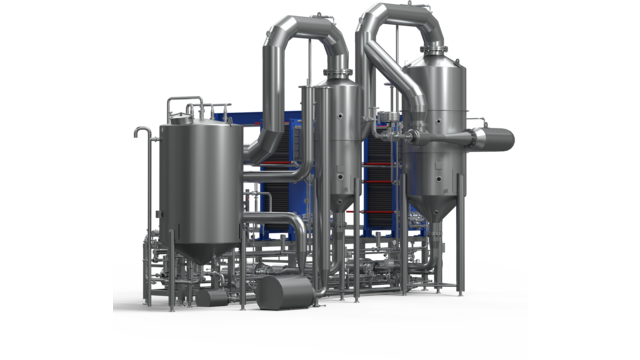

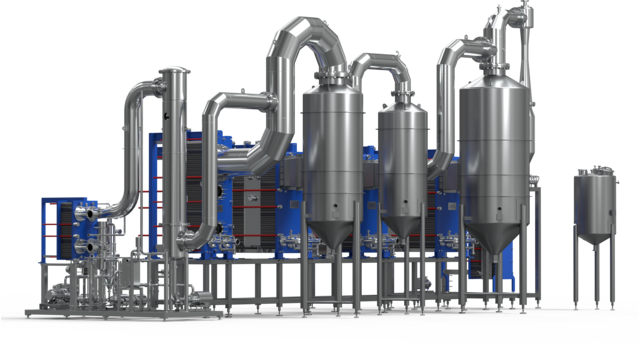

Completely engineered and pre-assembled evaporation systems

Applications

Food and beverage

- Fruit juices and purées

- Sugars, syrups (corn), honey and confectioneries

- Ethanol stillage

- Meat and vegetable broths

- Gelatine and collagen peptides

- Fermentation products

- Coffee and tea

- Vegetable protein

- Milk and whey protein

- Non-dairy plant drinks (oat, nut, etc.)

- Beer de-alcoholization

- Herbal extracts

Starch and sweeteners

- Sugars (beet, cane, potato, etc.)

- Glucose, dextrose, fructose, maltose

Proteins

- Gelatine

- Stick water

- Meat and fish broths

- Insect protein slurries

- Plant-based proteins

Chemicals and wastewater

- Caustic (NaOH, KOH, LiOH)

- Zero liquid discharge

- Inorganic salts

- Biofuels

Life science/industrial fermentation

- Fermentation broths

- Lysine

- Lactic acids

- Citric acids

- Amino acids

- Yeast extract

Services

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems

Integrating evaporation and crystallization for efficient solids recovery

There is a significant overlap between evaporation and crystallization, as both processes rely on the controlled removal of solvent to concentrate and purify product streams. By combining an evaporator with a crystallizer, manufacturers can take advantage of shared thermal energy and process synergies.

Purpose-built crystallization equipment allows for the precise formation of crystals during the final stages of evaporation, enabling the recovery of high-purity solid products such as salts, proteins, and specialty chemicals.

Alfa Laval evaporation systems serves as integral parts of crystallization systems.

This integrated approach maximizes efficiency, reduces energy consumption, and enhances overall yield in industries ranging from food and dairy to pharmaceuticals and chemicals.

Pilot testing and rentals of evaporation systems

Try before you buy. Get expertise and advice from Alfa Laval engineers for the optimum configuration for your evaporation system, including:

- Detailed water analysis and characterization

- Process and water chemistry modelling

- Benchmark and/or pilot testing for moderate- to high-risk applications

- Detailed material compatibility evaluation

- Sample analysis

- Pilot tests

Visit the Alfa Laval Materials Technology & Chemistry Lab and Test Centre in Lund, Sweden, the Alfa Laval Innovation and Test Centre in Nakskov, Denmark, or rent one of our mobile pilot evaporation systems to conduct onsite trials at your plant.