Maritieme keteloplossingen voor LNG als brandstof

Naarmate de scheepvaartsector verduurzaamt, zijn Alfa Laval Aalborg scheepsketels klaar om te werken met duurzamer LNG-brandstof. Het brandstof-flexibele Aalborg ketelplatform van vandaag maakt een eenvoudige configuratie voor LNG mogelijk, of u dit nu direct wilt toepassen of later een LNG-conversie wilt uitvoeren. Onze ketels zorgen voor een hoogrendementsproductie van stoom of warm water, zowel op LNG als op olie of biobrandstof als back-up. Bovendien kunnen ze de cruciale veiligheidsfunctie vervullen van het beheren van LNG boil-off gas (BOG). Dus meer dan alleen compatibel zijn met LNG als brandstof, maken onze ketels de overstap naar LNG eenvoudiger en kosteneffectiever.

Waarom kiezen voor Alfa Laval Aalborg ketels voor LNG?

Overschakelen naar LNG gaat verder dan alleen de motor. Ook uw gestookte ketel moet worden voorbereid, en Aalborg-ketels zijn de LNG-standaard van vandaag.

- Produceer stoom met LNG als brandstof – met dual-fuel back-up in de vorm van oliën en biobrandstoffen

- Beheer BOG veilig met behulp van de ketel (gasregelstraat vereist voor ketels met een capaciteit van meer dan 45.000 kg/u)

- Bereid u kostenefficiënt voor op de toekomst, door te kiezen voor een LNG-ready configuratie die een latere upgrade vergemakkelijkt

- Geniet van gemoedsrust, gegarandeerd door een robuust ontwerp, wereldwijde service en onze 100+ jaar ketelervaring

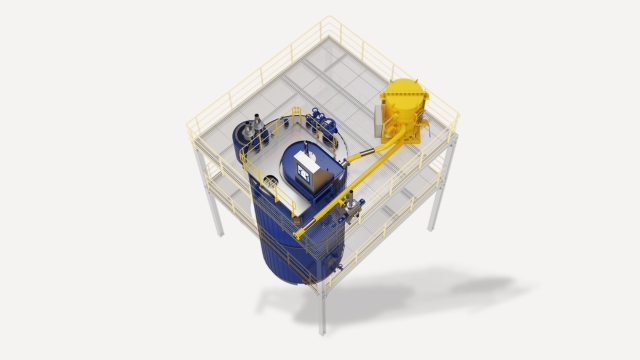

Een flexibel boilerplatform voor de overstap naar LNG

Alfa Laval Aalborg ketels zijn klaar voor elke brandstof in de maritieme transitie naar nul CO2-uitstoot – en ze kunnen ook worden geconfigureerd als elektrische hybrides. Naast het werken met oliën en biobrandstoffen, kunnen ze worden ingericht om één alternatieve brandstof naar keuze te gebruiken. Voor een groeiend aantal reders is die keuze LNG, wat de CO2-uitstoot met maximaal 25% vermindert.

Als u nu nog niet klaar bent om over te stappen op LNG, kunt u uw schip toch toekomstbestendig maken met LNG in gedachten. Nieuwe Aalborg ketels kunnen worden geïnstalleerd in een LNG-ready configuratie, met een gasgeschikte brander, een aangepast drukdeel en gereserveerde ruimte om later LNG-componenten toe te voegen. Dat betekent niet alleen een lagere investering vandaag, maar ook een kosteneffectieve LNG-conversie in de toekomst.

LNG-ketels voor veiligheid en stoom

Alfa Laval is geen onbekende op het gebied van LNG-veiligheid en levert al vele jaren Gasverbrandings-units en inertgassystemen aan LNG-carriers. Die ervaring komt tot uiting in onze LNG-keteloplossing. Naast het produceren van stoom met LNG als brandstofbron, biedt onze oplossing u de mogelijkheid om:

De LNG-tankdruk te regelen

De ketel kan worden gebruikt om LNG boil-off gas (BOG) te verbranden, waarbij stoom wordt geproduceerd die kan worden benut of naar de dumpcondensor kan worden geleid. Dit kan voordelig zijn tijdens een havenverblijf, bijvoorbeeld wanneer de energie van een hulpwerktuig niet kan worden verbruikt. Omdat de brander indien nodig een vrije doorstroming vanuit de tank aankan, biedt deze ook een belangrijke veiligheidsbackup als uw compressietrein zou uitvallen.

Gemengd inert gas en methaan af te voeren

In tegenstelling tot hoofdmotoren of generatoren kan de ketel het mengsel van inert gas en methaan verbranden dat vrijkomt tijdens het gasvrij maken en opgassen. Bij inspecties betekent dit dat u direct naar het droogdok kunt gaan, zonder een omweg te maken voor gasafvoer.

Voor de meeste ketelcapaciteiten is alleen de compacte gasafsluiterunit nodig voor deze mogelijkheden. Voor ketels met capaciteiten van meer dan 45.000 kg/u is een volledige gasafsluiterinstallatie vereist.

LNG-ketels voor alle soorten behoeften

Ons Alfa Laval Aalborg-ketelplatform ondersteunt zowel LNG als brandstof als het volledige scala aan behoeften voor scheepsketels. Ontdek ons ketelassortiment hieronder of neem contact met ons op om de juiste oplossing voor u te bespreken.

Aalborg OS-TCi

Kleine tot middelgrote capaciteiten

De Alfa Laval Aalborg OS-TCi is bedoeld voor hulpgebruik en is een gestookte scheepsketel voor de productie van stoom. Ontworpen met helixbuizen die een groter warmteoverdrachtsoppervlak bieden dan conventionele oplossingen, levert hij brandstofbesparende efficiëntie.

- Ontwerpdruk: 10 bar(g)

- Capaciteit: 1200–8000 kg/u

Aalborg OC-TCi

Composietketel/economizer

De Alfa Laval Aalborg OC-TCi is een maritieme composietketel voor het produceren van stoom door verbranding en/of warmteterugwinning uit rookgas. Met zijn hoge efficiëntie en het vermogen om thermische energie terug te winnen, kan hij helpen de milieu-impact te verminderen.

- Ontwerpdruk: 10 bar(g)

- Capaciteit: 1200–6500 kg/u (gestookt gedeelte) / 300–5000 kg/u (rookgasgedeelte)

Aalborg OL

Grote capaciteiten

De Alfa Laval Aalborg OL is een hoogcapaciteits, gestookte scheepsketel voor het produceren van grote hoeveelheden stoom of warm water. Beschikbaar in twee ontwerpdrukken, heeft hij een topgestookt ontwerp dat warmteoverdracht maximaliseert en drukverlies minimaliseert.

- Ontwerpdruk: 9 of 18 bar(g)

- Capaciteit: 10.000–50.000 kg/u

Een betrouwbare partner op uw LNG-reis

Het huidige Alfa Laval Aalborg-ketelplatform bouwt voort op een eeuw aan ketelervaring en onze lange praktijk in het werken met LNG, aangevuld met gespecialiseerd onderzoek in het Alfa Laval Test & Training Centre. De ketels, branders en alle sleutelonderdelen – waaronder de gasafsluiter en de afzuigventilator voor LNG-toepassing – worden intern ontworpen en geproduceerd om kwaliteit, veiligheid en duurzaamheid te waarborgen. Daarnaast worden onze ketels ondersteund door het Alfa Laval Marine Service-netwerk. U kunt rekenen op 24/7 service en ondersteuning wereldwijd, plus een compleet serviceaanbod om uw ketels in topconditie te houden.