Testing equipment and capabilities for processing alternative proteins

The ability to perform reliable tests that accurately predict full-scale process behavior is crucial when optimizing existing processes or experimenting with new recipes and raw materials.

Alfa Laval offers a special range of test and pilot-scale equipment, including all core components required in alternative protein production. You can also perform tests together with our experts at our test centers in Sweden and Denmark. Choosing Alfa Laval equipment ensures consistent results when scaling up and minimizes risk, time, and cost during commercialization.

So, whether you are a start-up, a technology center, or an established producer, we have the solution for you.

The testing journey

From lab-scale testing to large scale production, your testing journey is tailored to your needs, with expert guidance at every step.

Depending on your preferences, you can purchase or rent all the necessary equipment, or perform all the required tests at our test facilities.

Our compact plug-and-play pilot skids make it easy to perform tests to establish proof of concept and assess performance, facilitating process optimization and scale-up.

Our team of application experts is glad to assist when you are testing and developing new recipes and processes or optimizing existing processes.

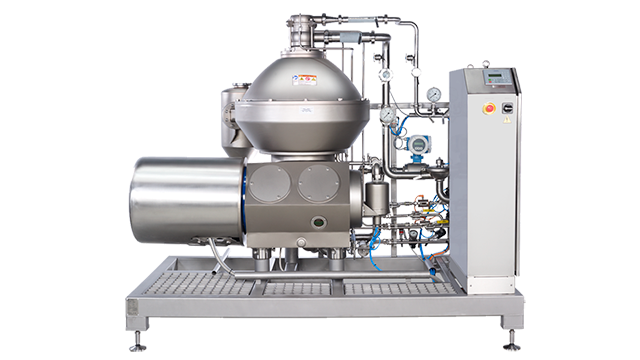

Separator test units

We help you find the ideal separators for your processes. We offer extensive testing possibilities, allowing you to test our equipment throughout your development process – from initial lab tests, via pilot tests, to full-scale production.

You can perform tests at your site using equipment from our Equipment Pool. Our Equipment Pool has a wide range of separator models suitable for different alternative protein separation duties, making it easy to test and find the optimum equipment for your process and raw material before investing.

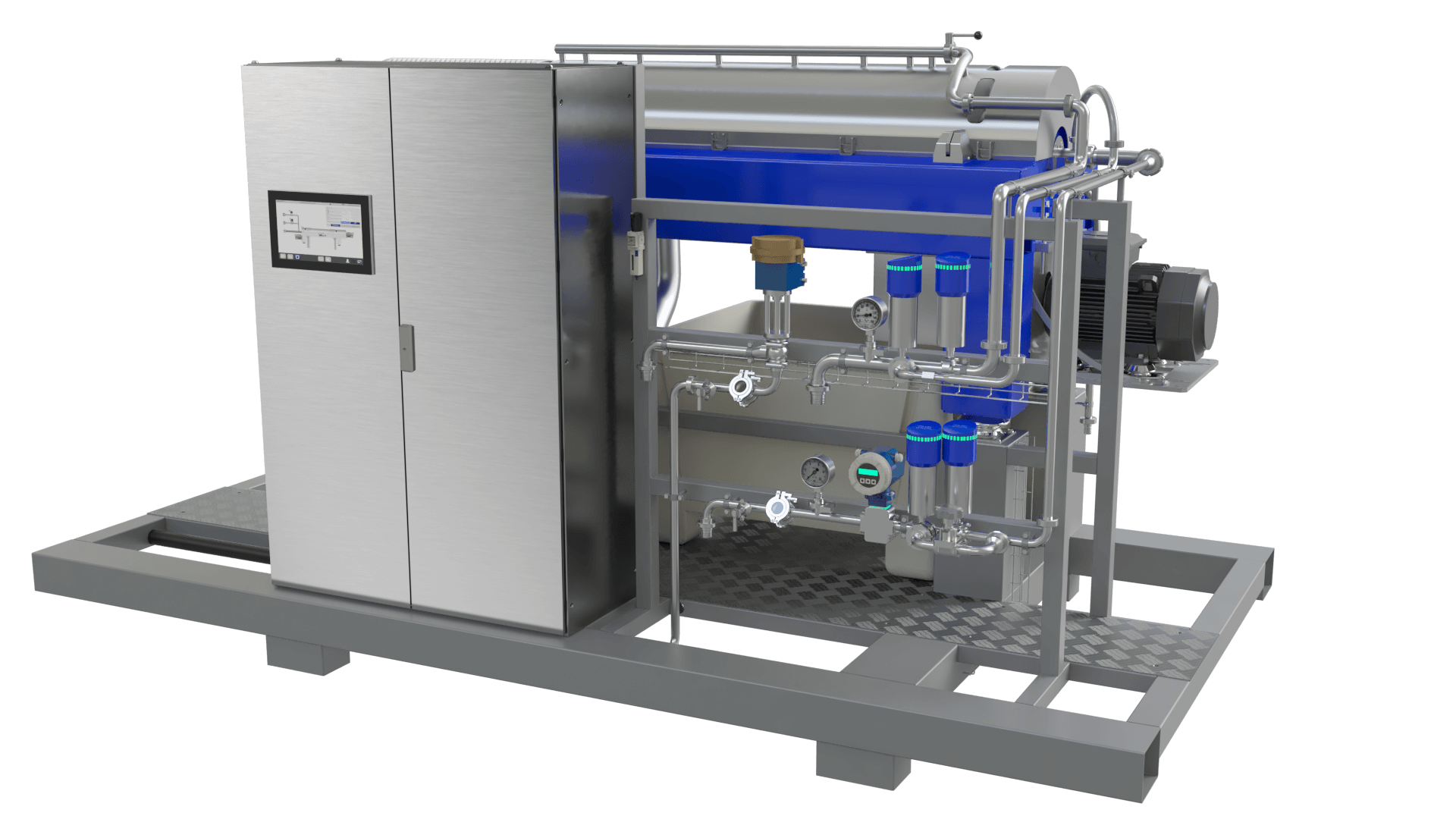

Foodec test modules

The Alfa Laval Foodec pilot decanter skids are compact, easy to install and operate, and offer valuable insights when developing new products or optimizing existing processes.

Foodec decanter skids are available for models of different sizes and can be configured to match your trial and/or production requirements. These skids are equipped with an advanced control system, making it easy to adjust parameters and refine lab tests. As a result, validating performance before scaling up to commercial production has never been easier.

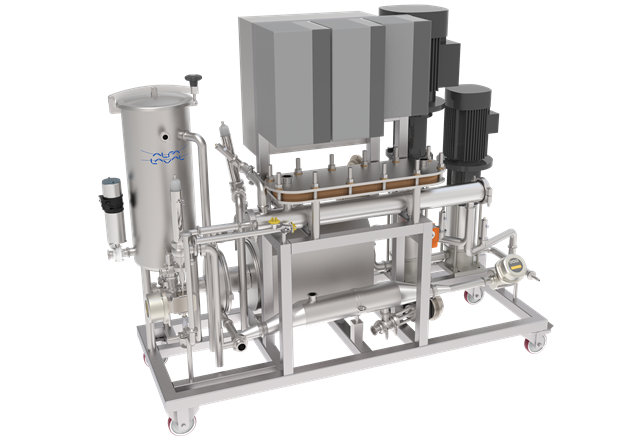

Membrane test units

Alfa Laval offers fully integrated membrane filtration systems for R&D, upscaling, and process optimization. We offer units in sizes suitable for lab and pilot-scale test runs. These units make it easy to test different membrane types, and you get valuable insights about the concentration that can be achieved, how liquids with varying viscosities behave, indications of fouling and cleaning properties, data on the purity of the protein fraction, and the expected yield.

With our test units, you can:

- Get insights about the long-term stability of the process.

- Receive solid data before scaling up to commercial production.

- Produce product samples that can be sent to potential customers.

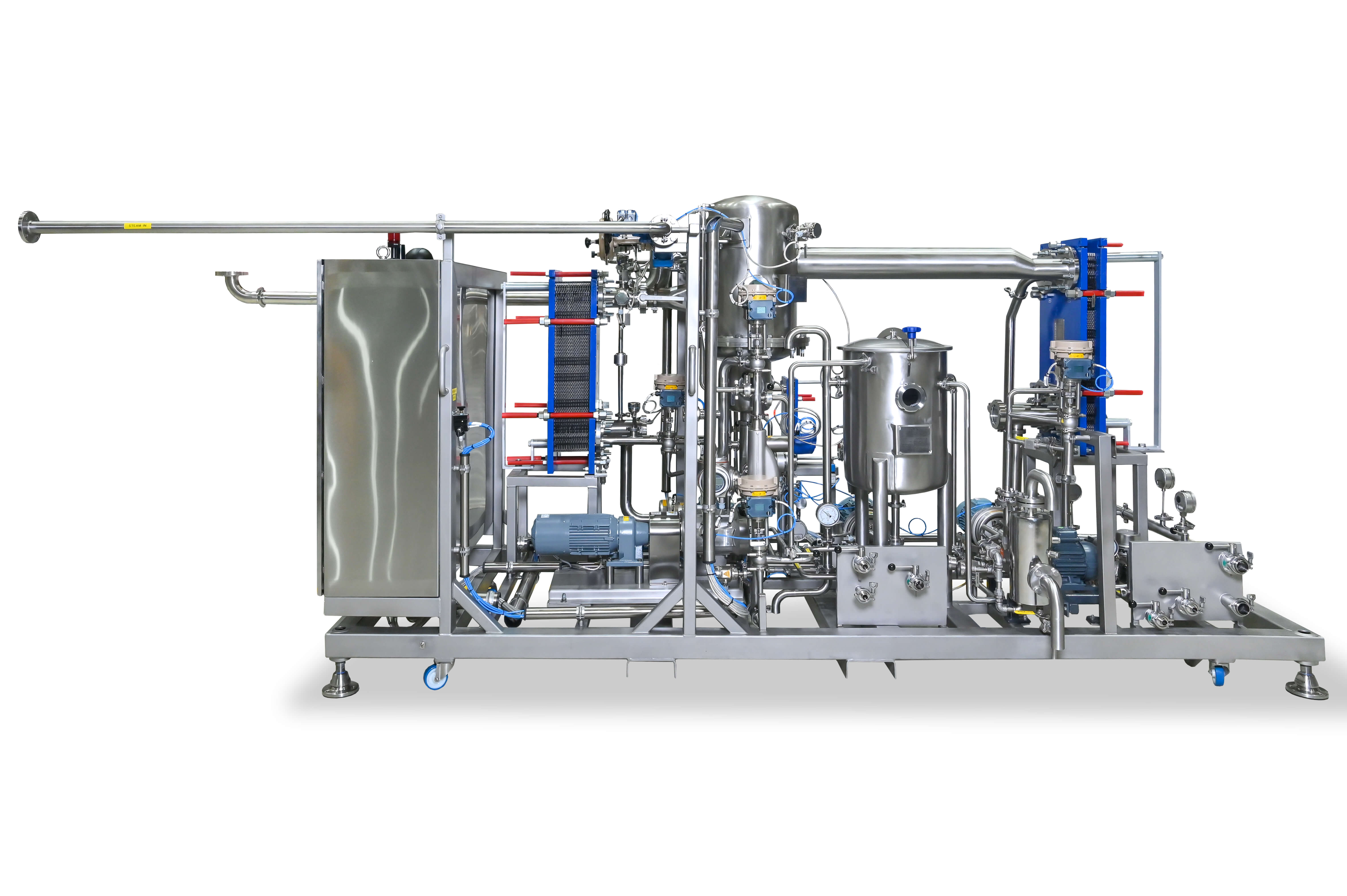

Evaporation test units

Verify performance, efficiency, and cleaning requirements directly on site with an Alfa Laval mobile pilot evaporation system or conduct tests at the Alfa Laval Innovation and Test Centre. Our team of process specialists will help you find the optimum solution based on your requirements and operating conditions.

Our test centers for scalable protein technologies

From lab-scale trials to full-scale production—partner with us to validate, optimize, and scale your processes.

Across our specialized test centers in Denmark and Sweden, we offer hands-on collaboration and cutting-edge facilities to help you develop, validate, and scale your alternative protein processes. Whether you're working with plant-based proteins, fermentation, or cultivated meat, our experts and equipment are ready to support you—from lab-scale trials to full-scale production. Each center is tailored to specific technologies, ensuring you get the right expertise and tools at every stage of your innovation journey.se.

Learn more about the facilities and contact us to book a trial.

Kolding Test Center – Process optimization at scale

Our Kolding facility in Denmark specializes in optimizing both new and existing processes using your specific ingredients and parameters. We offer validation and quantification services across batch sizes from 25 to 20,000 liters, supported by a broad range of hygienic equipment for mixing, dispersion, pumping, heating, cooling, tank cleaning, and valve automation. You can join the trials on-site or via live link.

Our next-generation food setup supports biomass and precision fermentation, plant-based proteins, and cultivated meat. We focus on improving sustainability, cost-efficiency, yield, uptime, and flexibility—empowering you to process diverse recipes and batch sizes with a single solution.

Nakskov Test Center – Membrane solutions from lab to production

At our Nakskov center in Denmark, we specialize in membrane technologies for food applications. We support testing from lab scale (starting at 500–1000 mL) to pilot and full-scale production. Our equipment includes flat sheet membranes and spiral membrane elements, enabling classic applications in fermentation and protein processing.

We collaborate closely with you throughout the testing journey, ensuring seamless scale-up and tailored membrane solutions.

Søborg Test Facility – Decanter performance under extreme conditions

Our Søborg facility in Denmark is dedicated to performance innovation, offering both short- and long-term testing capabilities for decanters. The center includes a workshop and advanced stress testing environments, exposing equipment to temperatures from -40°C to +60°C and humidity levels up to 95%.

We help you validate equipment durability and reliability under real-world conditions, ensuring robust performance across diverse food processing environments

Flemingsberg Food Lab – Collaborative testing for separation solutions

Our Food Lab in Tumba, Sweden combines demonstration and testing capabilities with deep centrifuge expertise. We conduct R&D testing for future solutions and customer trials using your feedstock, supporting a wide range of food applications including fermented products and fermentation processes.

Our comprehensive toolbox enables detailed customer sample analysis, and our team communicates through a shared analytical language to ensure clarity and precision. You can participate in trials on-site or remotely by sending samples for testing.