Energy efficient clean hydrogen solutions

Why hydrogen is the fuel of the future

As 47% of the world’s industries aren’t compatible with electrification, we will need viable alternatives to fully move away from fossil fuels. Clean hydrogen will be one of them. In fact, the growing demand for renewable and low carbon hydrogen means that it could represent over 20% of the world’s energy demand by 2050.

Hydrogen is a suitable energy carrier and feedstock for many applications, especially in the hard-to-abate sectors. So, providing that it comes from renewable and low-carbon sources, this could be a vital component on the road to net-zero. We can already see the key role that hydrogen, and its derivatives, will play in several industries, like chemical and steel production. It can also be used as fuel in marine and on/off road transportation sectors, as well as providing flexible power generation.

The vital role of energy efficiency in hydrogen solutions

Alfa Laval offers the widest range of energy efficient heat exchangers for renewable hydrogen production, distribution, transportation, storage, and use. After 90 years perfecting our proven technologies, Alfa Laval is the partner for all kinds of heating and cooling applications across the hydrogen economy, supporting the industry as it scales up and accelerates the energy transition.

The combination of Alfa Laval’s heat transfer expertise and global manufacturing capabilities make us the right partner in everything from energy efficient electrolyser cooling, balancing-of-plant, and freshwater generation to fuel cell development and dispenser pre-cooling in refuelling stations.

Did you know that 20-40% of the energy generated by electrolysers is lost as heat? Alfa Laval’s heat transfer technology ensure efficient electrolyser cooling, balancing-of-plant and enables heat reuse.

Explore how Alfa Laval can optimize your electrolyser cooling processes.

2. Water purification for hydrogen production

High water quality is essential in renewable hydrogen production. But did you know that Alfa Laval’s heat transfer technology makes it possible to use sea or river water in renewable hydrogen production, at the same time as increasing the system efficiency?

Find out more about what Alfa Laval can offer in water purification.

Converting renewable electricity into vital molecules requires a broad system perspective. Alfa Laval’s expertise and wide range of heat transfer technology can offer efficient heating and cooling in any power-to-X application.

Find out how Alfa Laval can support Power-to-X on an industrial scale.

4. Fuel cell system optimization

Converting hydrogen-based fuels back into power is made possible with fuel cells. Alfa Laval’s advanced heat transfer technology allow for reliable heat performance and enable development and scale up of fuel cell system solutions.

Explore how Alfa Laval supports fuel cell systems optimization.

5. Pre-cooling in hydrogen refuelling

Efficient and safe hydrogen refuelling is important to support a viable, hydrogen-based transportation infrastructure. Alfa Laval’s heat transfer technology allows for optimized pre-cooling in hydrogen refuelling solutions.

Discover Alfa Laval’s unique solution designed to optimize pre-cooling in hydrogen refuelling.

Renewable hydrogen value chain

How clean hydrogen is produced

Renewable hydrogen is produced using an electrolyser, where renewable electricity splits water molecules into hydrogen and oxygen.

Whether you are using PEM, Alkaline or Solid Oxide electrolyser technology, Alfa Laval has an energy efficient and scalable solution for you. Our heat transfer technology can support you with everything from cooling electrolytes and gases, to recovering excess heat, and balancing of the plant.

On top of that, our freshwater generation technologies make it possible for our customers to reuse the excess heat from their electrolyser, while also converting sea or river water into the pure water needed for these applications.

How clean hydrogen is used

Hydrogen is a clean fuel that can be used in many different sectors, as a feedstock for chemical and material production, a fuel for power, and heat generation in both industrial scale and decentralized solutions. It can even be used as fuel in heavy transportation.

Alfa Laval supports heating and cooling needs across the hydrogen value-chain, covering everything mentioned and more. We have products that have been specifically created for fuel cell development, hydrogen refuelling, and industrial balancing of plant. And thanks to our global manufacturing capabilities, we can support efficient utilization of hydrogen and its derivatives.

Join the conversation – watch our webinar

In our latest webinar, “Bending the cost curve in hydrogen production”, Alfa Laval experts are joined by clean hydrogen frontrunners from Lhyfe and CEA Liten. Together, they explore the biggest obstacles and solutions for scaling renewable hydrogen globally.

Low carbon hydrogen enabled by carbon capture

Many technologies and solutions come into play when it comes to accelerating the energy transition, including low carbon hydrogen. This is hydrogen that is produced from efficient carbon capture technology that helps transition away from traditional fossil fuel sources. Want to discover what Alfa Laval offers in carbon capture technologies?

Energy storage crucial in renewable build-out

Storing intermittent renewable energy for later use will be crucial to unlock the energy transition. Many different energy storing technologies will come into play, and we are ready to support all of them. Want to know more about Alfa Laval’s offerings in energy storage?

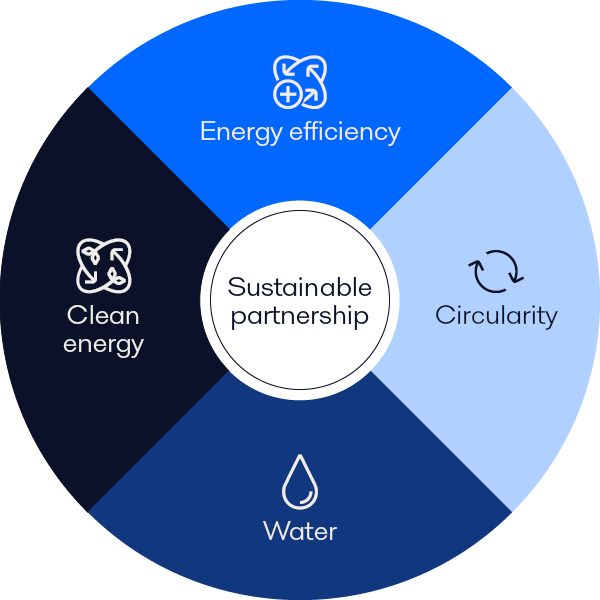

Collaboration accelerates the energy transition

Collaboration across borders is a vital part of accelerating the energy transition. That is why Alfa Laval joined 150 companies worldwide, as a proud supporting member of the Hydrogen Council. The member companies are working together to develop hydrogen solutions across the value chain and foster the clean energy transition.

A 360° view on activating a hydrogen ecosystem

Hydrogen and its derivatives are crucial in the energy transition and we need to collaborate to achieve a successful full-scale ecosystem from power-to-X-to-power.

That's why Alfa Laval gathered 30 stakeholders across the hydrogen value chain to explore a 360° view on accelerating the activation of a hydrogen ecosystem.

Curious about our technologies and solutions in hydrogen?

Contact us today for more information on Alfa Laval's solutions related to hydrogen. Our experts are ready to support you,