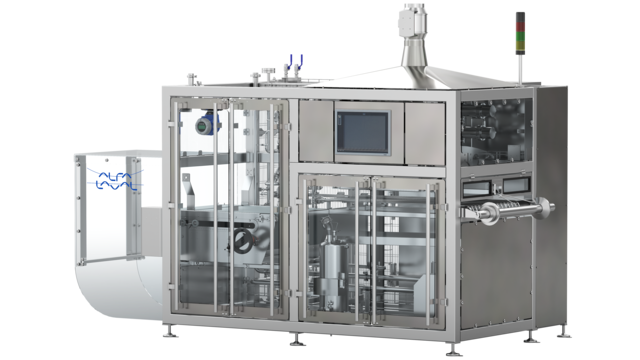

High speed low acid aseptic filler

Versatile aseptic bag-in-box filling system for use with juices, beverages, purées and dairy products.

Alfa Laval Astepo HS-LA aseptic bag-in-box fillers are ideal for packaging food and beverage products that feature either high or low acidity (pH <4.5 and pH >4.5), at rates of up to 12,000 litres/hour. See video below.

Typical uses include:

- Fruit juices, concentrates, purées and beverages

- Dairy products, such as UHT milk, flavoured milk, soft ice mix and cheese sauce

- Sauces and condiments

- Syrups and post-mix products

Good control, extreme accuracy

These fillers employ brushless electric servomotors that make it possible to control and adjust all the movements with extreme accuracy.

This results in faster filling as well as greater overall reliability.

Easy to integrate

The high speed low acid fillers work with any type of international-standard 1-inch spouts. They are available as stand-alone modules, or integrated into a wide range of Alfa Laval food processing lines. A wide range of optional equipment is also available.

These fillers can also be linked up to an automatic Combibox cartoning line (featuring carton sealing with hot-melt glue or adhesive strip).

Benefits

- Extremely accurate filling boosts reliability and reduces waste

- Exceptional standards of hygiene that your customers can rely on to maintain each product’s specified shelf life

- Compliant with any type of international-standard 1-inch spouts, for maximum versatility

- User-friendly automatic operation, with only minimal supervision and maintenance required

- Compact, “plug and play” unit that’s easy to install

Fonctionnement

How it works

Exceptional standards of hygiene

Before production starts, all surfaces in contact with the food product are automatically sanitized and sterilized. If any alarm is set off during these processes, the time counter is automatically set to zero and does not restart until the condition that triggered the alarm has been dealt with.

Surfaces not actually in contact with the product being filled into the bags, such as the filling head and the tunnel, are sterilized with steam and vaporized hydrogen peroxide.

Operation

The bags are delivered pre-irradiated with gamma rays. Caps are of the flat rigid type, with high or low fitments, or other dispensing caps from major suppliers.

The operator only has to introduce the first bag. The bag feeder then automatically transfers the bags into the sterilization tunnel and the filling head.

After this the cap is re-inserted in the bag spout and an automatic cutter separates the filled bag from the web. A motorized roller conveyor moves the filled bags out of the machine.

The control panel includes a PLC to manage and check all phases of the filling operation and the conditions within the filler machine.

Filling

In the sterilization tunnel, the caps are sterilized with a jet of vaporized hydrogen peroxide. The spouts are then introduced inside the aseptic head, where a positive flow of sterile air keeps out any airborne contaminants.

The temperature and the positive pressure inside the chamber are constantly monitored, because this is critical for hygiene standards.

The use of brushless electric servomotors means the HS-LA filler can control and adjust the movements, speed and acceleration of the aseptic valve with considerable precision. This ensures highly accurate filling, with no waste.

Caps are removed by pincers, and an air seal system closes the spout to prevent any contaminants from entering the bag.