Filtres à combustible

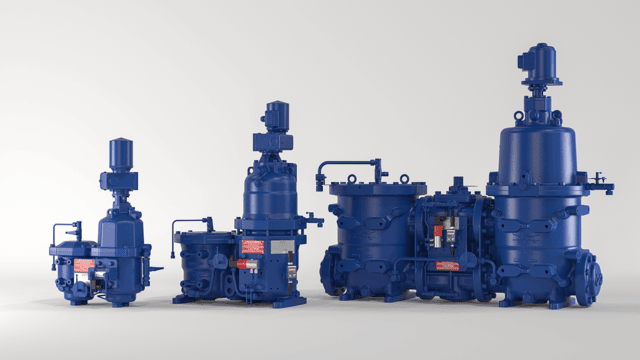

Alfa Laval fuel oil filters provide full-flow filtration of heavy fuel oils for two-stroke and four-stroke diesel engines. They are available in a large range of filtration grades, including fine filtration grades for better protection against pollutants such as catalytic fines.

Fuel oil filters

The F type range of Alfa Laval automatic fuel oil filter systems provides effective full-flow filtration of fuel oil (FO), heavy fuel oil (HFO) and marine diesel oils (MDO) up to 700 cSt/50°C. These fuels are widely used in modern two-stroke and four-stroke diesel engines, and the quality and cleanliness of such fuel has an important influence on engine efficiency, fuel consumption, reliability and service life.

This range of automatic fuel oil filter systems only requires very limited investment yet helps ensure reliable engine operation, along with peace of mind for those dependent on the engine working as intended. The robust, space-saving design makes these units easy to install as well as to retrofit as upgrades to existing installations.

These units use fuel oil that has already been filtered to backflush the filters, doing away with any need for a compressed air supply. This backflushed oil is then cleaned by refiltration in a special filter-equipped diversion chamber (which also uses the same backflushing principle) before being recirculated into the system. This diversion chamber acts as an automatic maintenance-free sludge treatment system, collecting and concentrating the particles backflushed from the full-flow chamber and the subsequent cleaning process into a concentrate sludge.

This means there is no need for a sludge treatment unit involving either manual cleaning or consumables that need replacing. Installation is recommended on the circulation side (hot loop) of the fuel oil system for maximum engine protection. Eliminating the use of colder backflush media prevents thermal shocks that can result in the formation of asphaltenes in the fuel. Options are available for additional features, such as a drain valve with an automatic timer, and a built-in changeover valve with bypass filter, enabling operations to continue uninterrupted during routine maintenance.

Fonctionnement

Éléments filtrants avec surface de filtration optimisée

Un distributeur, entraîné par un moteur électrique au-dessus du filtre, alimente ensuite en combustible la série d'éléments filtrants. Chaque élément filtrant comprend un châssis en aluminium et un tamis en inox. Chaque élément est divisé en quartier, tel un camembert. Les éléments filtrants sont empilés et les quartiers huit colonnes filtrantes indépendantes à plein débit.

Le distributeur tourne régulièrement, remplissant sept des huit colonnes filtrantes à plein débit. Les solides s'accumulent à la surface du filtre et l'huile filtrée s'écoule vers le moteur.