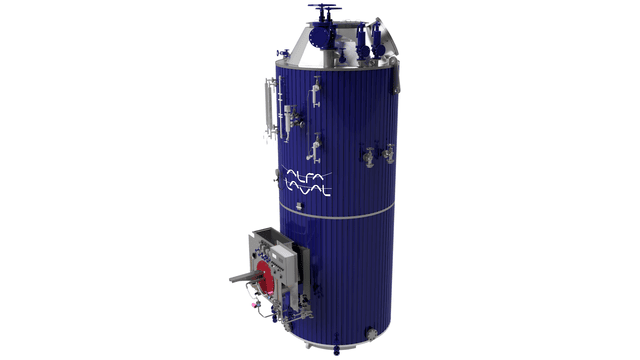

Aalborg OM-TCi

Aalborg OM-TCi is a vertical cylindrical steam boiler with a high capacity range. OM-TCi has been developed based on our well-proven technology and long experience.

Aalborg OM-TCi (formerly MISSION™ OM-TCi) is a vertical cylindrical steam boiler in the capacity range of 8,000 - 20,000 kg/h. It has been developed based on our well-proven technology and long experience.

The best features of the well-known UNEX™ CHB and MISSION™ OM boilers have been incorporated into the new boiler design.

Caractéristiques et avantages

- Chaudière marine cylindrique verticale

- Rendement thermique élevé de 89 à 92 % dès la conception standard

- Système de commande sur mesure basé sur un PLC avec IHM à écran tactile

- Prête à installer

- Conçue pour fonctionner avec un brûleur à coupelle rotative ou un brûleur à atomisation de vapeur

Fonctionnement

Corps de chaudière

L'Aalborg OM-TCi se compose d'un corps de chauffe avec des parois étanches au gaz. Le nombre de tuyaux de descente a été optimisé pour assurer une circulation naturelle sûre, et le dimensionnement adéquat du corps de chauffe garantit une bonne combustion et de faibles émissions, une charge modérée et de faibles contraintes sur les matériaux.

Convection

Une enveloppe cylindrique entoure les tubes de fumée et l'espace eau/vapeur. Ces tubes de fumée ont des caractéristiques de transfert de chaleur améliorées qui fonctionnent avec une faible température des gaz d'échappement et donc un rendement élevé.

Brûleur multi-combustible et système de contrôle connecté

La chaudière est livrée avec un brûleur multi-combustible, conçu pour une régulation automatique en fonction de la demande de chaleur du système.

La capacité de régulation du brûleur est large : d’une combustion complète à un faible niveaux d'oxygène. Pour assurer une combustion optimale, de l'air comprimé ou de la vapeur est utilisé comme moyen d'atomisation.

Le brûleur s'ajuste automatiquement, mais l'opérateur peut passer en mode manuel si nécessaire. Le système de brûleur permet l'utilisation de divers combustibles alternatifs (biofuel, méthanol, ammoniac), ainsi que la combustion des gaz d'évaporation provenant des combustibles gazeux (fonctionnalité GCU, unité de combustion de gaz).

Le brûleur et la chaudière sont contrôlés par un système de contrôle spécialement conçu et standardisé, qui est inclus dans la livraison. Ce système comprend tous les composants nécessaires au système de récupération de chaleur selon les normes Alfa Laval, y compris le contrôle principal avec panneau IHM (Interface Homme / Machine) situé dans chaque salle des machines. Le système de contrôle permet la connectivité et la collecte intelligente de données, et offre une capacité d'assistance à distance.

Dans les systèmes à deux salles des machines : chaque salle dispose de son propre système de contrôle, mais ils communiquent et fonctionnent ensemble de manière transparente, ce qui permet des modes de fonctionnement flexibles.

Données de conception

· Puissance thermique : jusqu'à 14 MW

· Capacité de vapeur : 8 000 - 20 000 kg/h

· Pression de conception : 10 bar(g)

Types de navires

- Navire de croisière

- Pétrolier VLCC

- Pétrolier Suezmax

- Pétrolier Aframax

- Pétrolier Panamax

- Unité FPS