Spanish winery treats wastewater to reuse quality with Alfa Laval membrane technology

The Alfa Laval membrane filtration module enables Viña Ijalba to release treated wastewater legally and safely into the nearby river

DATE 2023-11-28

The Viña Ijalba Winery offers high quality products and operates with a high level of environmental awareness. In 2011 environmental contractor HIDECO (Hidráulica Depuración y Ecología, SL) installed a membrane bioreactor (MBR) incorporating an Alfa Laval membrane filtration module (MFM) for biological wastewater treatment. This not only enables Viña Ijalba to release treated wastewater legally and safely into the nearby river, it also gives the winery the possibility to re-use the water for irrigation when necessary.

A traditional winery located in Spain’s famous La Rioja wine region, Viña Ijalba is setting the standard for environmental awareness in and around Rioja – from its organic production to its extensive re-cycling and environmental certification.

Wine making requires large amounts of clean water for washing newly harvested grapes as well as equipment and facilities. However, the Viña Ijalba winery does not have a municipal sewage treatment facility nearby in the Logroño area. Therefore, to be allowed to discharge wastewater into the river near the plant it was necessary to treat it first to comply with the new, stricter local environmental regulations relating to effluent discharge.

The winery was looking for a completely reliable, simple to operate and maintain wastewater treatment solution capable of coping with seasonal load variations. Since the winemaking process varies from day-to-day, the solution also had to be able to handle variations in both load and composition of the raw wastewater.

MBR technology recommended

Viña Ijalba consulted HIDECO (Hidráulica Depuración y Ecologia, SL, an environmental contractor well-known in the Rioja area, specialized in the design of MBR wastewater treatment plants for wineries. The company recommended an MBR plant based around an Alfa Laval membrane filtration module (MFM) of the patented hollow sheet technology that combines the best features from the flat sheet and hollow fibre membrane technologies. It is also more compact than a conventional wastewater treatment plant, and the final effluent is of reuse quality.

Hideco has been a local Alfa Laval partner for several years, designing and installing decanters for industrial sludge treatment as well as incorporating Alfa Laval MFM’s in a number of MBR, primarily wineries.

Gravity operation with low pressure a key factor

Felipe García Chivite, Managing Director of HIDECO, explains that his company’s choice of membranes for its MBR plants is based on an earlier research and pilot project. One aspect of this project involved comparing different filtration membranes to determine the best solution for treating wine industry effluents. They chose the Alfa Laval hollow sheet type membrane module.

“The key factor with the hollow sheet membrane is the low pressure needed for filtration,” says Felipe García Chivite. “This results in important advantages. The gravity operated MFM operates with an exceptionally low transmembrane pressure (TMP) across the entire surface of the membrane. This means that the mixed liquor is not squeezed against the membrane surface, which reduces fouling and consequently the need for cleaning and chemicals consumption. Another advantage is the possibility to design a relatively simple system with minimum pumps or other auxiliary equipment that could complicate its operation.”

Meeting discharge criteria with effluent of reuse quality

The MBR effluent treatment system incorporating the Alfa Laval MFM 100 unit was installed by Hideco at Viña Ijalba in 2011 and has a capacity of 35-40 m3/d. Alfa Laval contributed with technical know-how and support during the design, installation and commissioning.

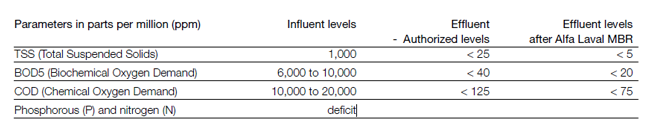

According to the winery, the MBR system’s performance has lived up to and surpassed expectations (see table). As specified, the quality of the treated water allows it to be discharged into the river, or used for irrigation if desired.

In the low season, when the need for wastewater treatment is much less, the winery reduces flux or stops the filtration for a number of hours, or even days, if necessary.

Viña Ijalba’s oenologist Pedro Salguero says: “ We are very happy with the new plant and have now solved our problems with both capacity and the quality of the treated water. We treat the wastewater from both the winery, the offices and from rain water, so now we are able to manage peaks quite well.”

Easy to maintain

To keep a continuously high membrane performance level, particles must frequently be removed physically from the membrane surface. Where other membrane systems need periodic back flushing requiring an extra pump (and additional costs and maintenance), the Alfa Laval MBR only requires periods of 2 minutes production stop every 10 minutes (periodic relaxation). This reduces the need for chemical cleaning, which is carried out using sodium hypochlorite (NaClO) three times per year and citric acid once/year before high season. The low dem

and for chemical cleaning was also a contributing factor for the selection of Alfa Laval membrane modules for Viña Ijalba.

Effective customer support

Thanks to the gravity operated Alfa Laval MFM module, the system has fewer pumps and a simpler control system than other technologies. Since there is less equipment, maintenance requirements are lower. However, Alfa Laval is always on hand locally to provide the the plant operator with service, maintenance and technical assistance on the MFM unit if needed.

Customer's voice

We are very happy with the new plant and have now solved our problems with both capacity and the quality of the treated water. We

treat the wastewater from both the winery, the offices and from rain water, so now we are able to manage peaks quite well

Viña Ijalba’s oenologist Pedro Salguero

The key factor with the hollow sheet membrane is the low pressure needed for filtration. This results in important advantages.

Felipe García Chivite, Managing Director of HIDECO

Download full story

Read the full story here.

PRODUIT - LE MBR

Le système modulaire de bioréacteur à membrane (MBR) combine le traitement secondaire et tertiaire des eaux usées et fournit un effluent de qualité supérieure (filtration efficace des boues jusqu'à 0,01 µm) adapté à la réutilisation des eaux traitées.

Une gamme complète de traitement des eaux & boues

Maximisez la réutilisation de l'eau, valorisez les déchets et réduisez la consommation d'énergie : nos équipements pour le traitement des eaux usées, la filtration et le traitement des boues permettent de produire des effluents propres pour le rejet ou la réutilisation de l'eau.